Vous avez pas d'articles dans votre panier.

-

MACHINES

MACHINES

- Nos Imprimantes FDM Our FDM Printers

- Nos Imprimantes Résines Our Resin Printers

- Nos Chambres UV & Lavage Our Wash & UV Box

- Nos Machines de Découpe Nos Machines de Découpe

- ANYCUBIC ANYCUBIC

- APEXMAKER APEXMAKER

- BAMBU LAB 🌈 BAMBU LAB 🌈

- COLOP COLOP

- CRAFT EXPRESS CRAFT EXPRESS

- CREALITY CREALITY

- CRICUT CRICUT

- ELEGOO ELEGOO

- EPSON EPSON

- FLSUN FLSUN

- MINGDA MINGDA

- MOSAIC MANUFACTURING MOSAIC MANUFACTURING

- PHROZEN PHROZEN

- PRUSA PRUSA

- RAISE3D RAISE3D

- SILHOUETTE SILHOUETTE

- SISER SISER

- SNAPMAKER SNAPMAKER

- UNIFORMATION UNIFORMATION

- UNIZ UNIZ

- xTool 💥 xTool 💥

- ZORTRAX ZORTRAX

-

SCANNERS 3D

3D SCANNERS

![banner right]()

-

FILAMENTS

FILAMENTS

![banner left]()

- FABRICANTS

MANUFACTURERS

[EMPTY] [EMPTY] [EMPTY] [EMPTY]

- 3D4Makers 3D4Makers

- 3DXTech 💪🏼 3DXTech 💪🏼

- AquaSys💧 AquaSys💧

- AzureFilm🔥 AzureFilm🔥

- Bambu Lab 🎋 Bambu Lab 🎋

- BASF ⚙️ BASF ⚙️

- ColorFabb ColorFabb

- Copper3D 🦠 Copper3D 🦠

- Creality Creality

- DSM DSM

- Elegoo Elegoo

- eSun eSun

- Extrudr Extrudr

- Fiberon by Polymaker 🔧 Fiberon by Polymaker 🔧

- FormFutura FormFutura

- Innovatefil Innovatefil

- Jamg He Jamg He

- Kimya Kimya

- Lattice Medical Lattice Medical

- Mitsubishi Chemical Mitsubishi Chemical

- Nanovia 🇫🇷 Nanovia 🇫🇷

- NinjaTek NinjaTek

- Owa Owa

- Panchroma by Polymaker 🎨 Panchroma by Polymaker 🎨

-

High Speed High Speed Effets Spéciaux Special Effect

- Matières Standard

Standard Materials

Charge ReinforcedMatières Ultra Perf Ultra Performance

- Matières d'Ingénierie

Engineering Material

Matières Haute Perf Hight Performance

- Propriété

Properties

[EMPTY] [EMPTY]

- Antibactérien Antibacterial

- Biosourcé Biobased

- Breakaway Support Breakaway Support

- Calcinable Cire Perdu Castable Lost Wax

- Contact Alimentaire (FDA) Food Contact (FDA)

- ESD - Antistatique ESD - Static Free

- Flame retardant UL94 Fire Proof UL94

- Flexible Flexible

- Hypoallergénique (Contact Peau) Hypoallergenic (Skin Contact)

- Isolant Electrique Electrical Insulation

- Expansé (Light Weight) Foaming (Light Weight)

- Radio-opaque X-ray Shielding

- Soluble Soluble

- Thermoréactifs Thermoréactifs

- UVréactifs UVréactifs

![banner right]()

- FABRICANTS

MANUFACTURERS

- REFILL REFILL

-

RÉSINES

RESINS

![banner left]()

- Résines LCD/DLP

Resin LCD/DLP

[EMPTY] [EMPTY]

- ALT RESINS (385 – 420nm) ALT RESINS (385 – 420nm)

- Antinsky Antinsky

- Anycubic Anycubic

- ApexMaker ApexMaker

- BASF BASF

- BlueCast (225 - 405nm) BlueCast (225 - 405nm)

- Creality Creality

- Detax Detax

- Elegoo Resin Elegoo Resin

- eSun Resin eSun Resin

- FunToDo (225 - 415nm) FunToDo (225 - 415nm)

- Jamg He 🆕 Jamg He 🆕

- Liqcreate (385 - 415nm) Liqcreate (385 - 415nm)

- Loctite Loctite

- Monocure3D (225 - 415nm) Monocure3D (225 - 415nm)

- Monocure Dental Monocure Dental

- Phrozen Phrozen

- Poc Lab - ESD-safe Poc Lab - ESD-safe

- Sunlu Sunlu

- UniFormation UniFormation

- Zortrax Zortrax

- Nettoyants Résine Resins Cleaner

- Résines Dentaires

Dental Resins

- BASF - Ultracur3D DM BASF - Ultracur3D DM

- Biocompatible - Dentaire Biocompatible - Dental

- Dentifix 225 - 415nm Dentifix 225 - 415nm

- Detax Freeprint Detax Freeprint

- eSun - Résines Dentaires eSun - Dental Resin

- Monocure3D - Rapid Model Dental Monocure3D - Rapid Model Dental

- Zortrax - Résines Dentaires Zortrax - Dental Resin

- Propriété Properties

![banner right]()

- Résines LCD/DLP

Resin LCD/DLP

-

xTool

xTool

-

DIY

DIY

- Machines de presse Hot press machines

- Four à Sublimation Four à Sublimation

- Presse Plate Presse Plate

- Presse Portable Presse Portable

- Presse Combo Presse Combo

- Mug Press Mug Press

- Accessoires/Consommables Accessories

- Feutres à Sublimation Feutres à Sublimation

- Films ThermoRétractables Films ThermoRétractables

- Papier Sulfurisé Papier Sulfurisé

- Supports personnalisables Customisable Media

- Matières & Consommables

Materials & Consumables

- 📃 Chemica 📃 Chemica

- 🔔 Siser 🔔 Siser

- 🌈 TeckWrap 🌈 TeckWrap

- Bande de Transfert Transfer Tape

- Flex/Thermocollant Flex/Thermocollant

- Imprimables Imprimables

- Métal/Foil Métal/Foil

- Papier/Carton Papier/Carton

- 📌 PLAQUES ACRYLIQUES 📌 PLAQUES ACRYLIQUES

- POSCA POSCA

- Sublimation Sublimation

- Stylos/Feutres Stylos/Feutres

- Vinyle Vynil

- Supports Personnalisables Supports Personnalisables

- Machines DIY

Machines DIY

- Button Press: Badgeuse Button Press: Badgeuse

- Imprimante UV DTF Imprimante UV DTF

- Minc : Applicateur de Foil Minc : Applicateur de Foil

- MoldPress : Machine à moules 3D MoldPress : Machine à moules 3D

- PrintMaker : Mini imprimante PrintMaker : Mini imprimante

- We R Memory : Outils Tout en 1 We R Memory : Outils Tout en 1

- xTool : Découpe Laser xTool : Découpe Laser

- Tufting Tufting

-

PIÈCES DÉTACHÉES

SPARE PARTS

-

ACCESSOIRES

ACCESSORIES

- Accessoires FFF/FDM Tools FDM/FFF

- Accessoires Résines Resins Tools

- Accessoires Scanners 3D Scanner 3D Accessories

- Kits Bambu Lab Kits Bambu Lab

- CNC - Inserts Filetés CNC - Inserts Filetés

- Outillages Tools

- Buses Nozzle

- BOFA - Extraction et filtration de fumée BOFA - Fume Extraction and Filter Technology

- SYNE Filtre Actif HEPA SYNE Active HEPA Filter

- Plaques Flexible Imprimante Résine Plaques Flexible Imprimante Résine

- FEP Shop FEP Shop

- Adhesion Plateau Plate Adhesion

- Magigoo Pen Adhésif d'impression 3D Magigoo Pen 3D Printing Adhesive

- Plateau Perforé Perforated Plate

- Buildtak Buildtak

- Ziflex Ziflex

- Ziflex Résine Ziflex Résine

- Bondtech Bondtech

- Accessoires Improve3D Improve3D Products

- Boîte de Stockage Storage Box

- Chambre UV UV Box

- Station de Lavage 2-en-1 Wash & Cure Machine

- Nettoyeurs Ultrasons Ultrasonic Cleaners

- Nettoyants Cleaners

- Masques & Protection Individuel (EPI) Masks & Personal Protection (PPE)

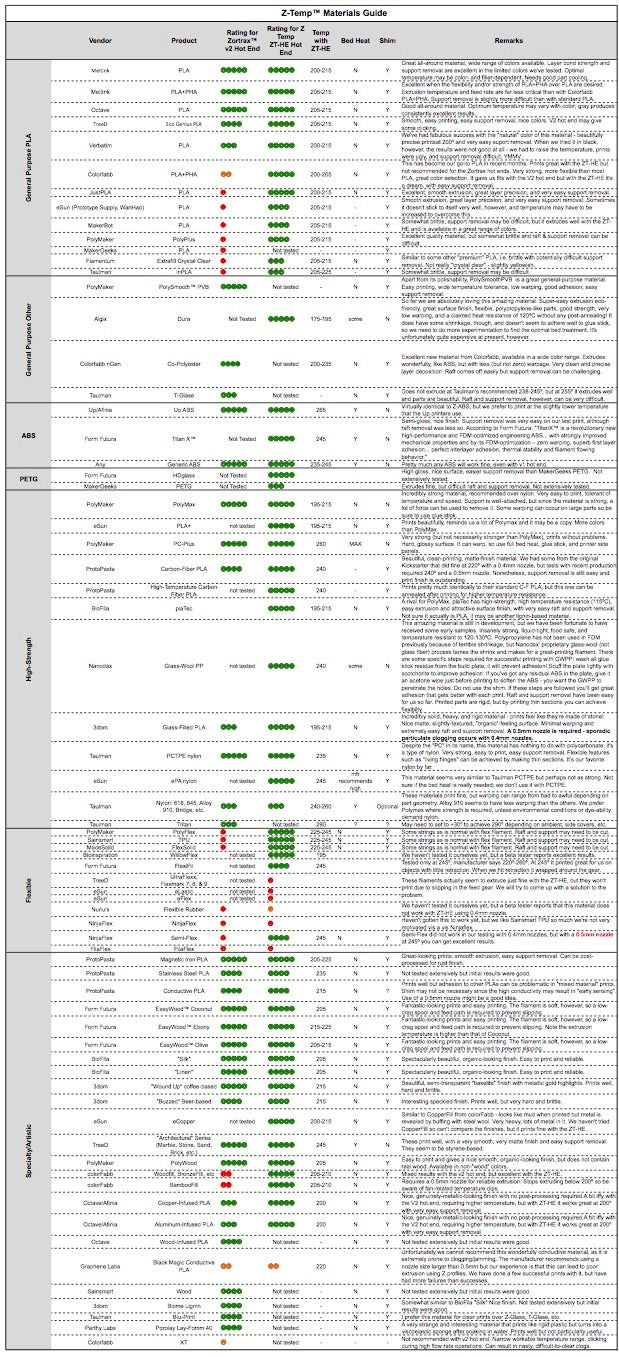

- Z-Temp (pour Zortrax) Z-Temp (for Zortrax)

- Logiciels Softwares

- Mintion Beagle Camera Mintion Beagle Camera

-

PACKS

PACKS

- Packs Imprimante 3D 3D Printer Packs

- Packs Scanners 3D 3D Scanners Packs

- Packs Filament Filament Packs

- Packs Résine Resin Packs

- Packs Bambu Lab Bambu Lab Packs

- Packs Artillery3D Artillery3D Packs

- Packs Outils & Accessoires Tools & Accessories Packs

- Packs Education Education Packs

- Packs Silhouette Cameo Silhouette Cameo Packs

- Packs Cricut Cricut Packs

![banner right]()

- SERVICES SERVICES

-

Bon Plan

Bon Plan

- 🚨 Déstockage eSun 🚨 🚨 Déstockage eSun 🚨

- 🚨 Déstockage Rosa3D🚨 🚨 Déstockage Rosa3D🚨

- 🚨 Déstockage Azurefilm🚨 🚨 Déstockage Azurefilm🚨

- 🚨 Déstockage Kimya 🚨 🚨 Déstockage Kimya 🚨

- 🚨 Déstockage Snapmaker 🚨 🚨 Déstockage Snapmaker 🚨

- 🚨 Déstockage Silhouette🚨 🚨 Déstockage Silhouette🚨

- 🚨 Déstockage Zortrax 🚨 🚨 Déstockage Zortrax 🚨

- Imprimantes 3D 3D Printers

- Consommables Consumables

- Accessoires Accessories

- Diy Diy

- PARTENAIRES PARTNERS

-

INFOS

INFOS

- Devenez Apporteur d'Affaires Become a Business Provider

- Univers Métiers Application & Industry

- Gazette du Maker Gazette du Maker

- Goodies Atome3D Goodies Atome3D

- Livraison & Logistique Delivery and Logistics

- Réception : Les Bons Réflexes Receiving parcels: Good habits

- Paiements & Garanties Guarantees & Payments

- Demande de devis Ask for a quote

- À Propos de Nous About Us

- Offres d'Emplois / Carrière Carreers / Job Offers

0

Mon panier:

Vous avez pas d'articles dans votre panier.